Fuel Pumps

Like the transmission cooler, the fuel pump seems to be a hotly contested topic. Here again there are many opinions out there about what pump is needed for a particular application. Many of the opinions that tend to surface on the various automotive message boards seem to suggest that OE-replacement pumps designed for a specific application can be used in other, higher-performance applications. In some cases, this may be true. But you need to understand how the typical fuel injected electric fuel pump works so you don't potentially put your engine's health at risk.

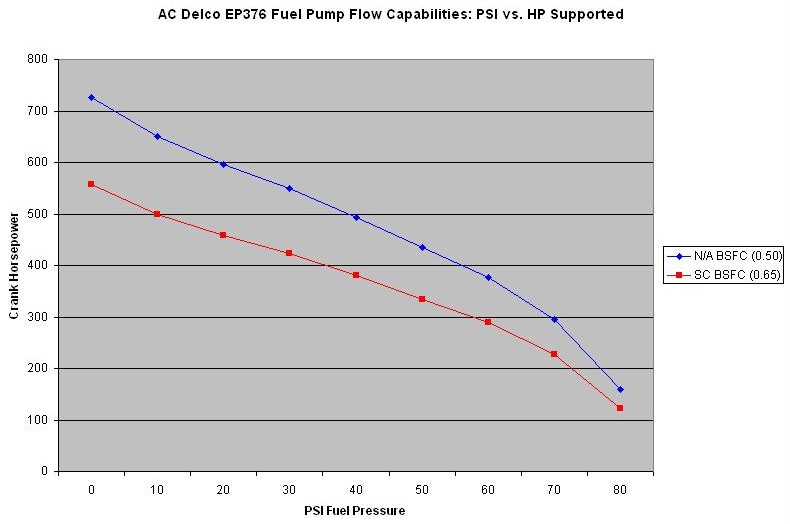

The typical electric fuel pump puts out a specific flow rate (volume) at a specific pressure level (PSI), assuming it gets all the electrical power (amps + voltage) it needs to do the job. Most, if not all electric pumps decrease volume of output when the pressure increases. Below is a chart constructed using flow test data from an AC Delco EP376 fuel pump calculated to show how much crank horsepower this pump will support...

In the above chart, you will notice two lines. The blue line (top) represents the amount of Crank Horsepower the EP376 pump will support on a naturally aspirated engine that consumes 0.50 lbs of fuel per HP it makes (also known as Brake Specific Fuel Consumption, or BSFC). The EP376 fuel pump was used on the Corvette LT1 V8 engine, and this engine had a maximum rated fuel pressure of 47psi. As you can see in the above chart, this pump is quite capable of supporting over 400hp on a naturally aspirated engine operating at less than 50psi of fuel pressure. Based on this data, it is reasonable to assume that the 300hp LT1 V8 Corvette engine was in no danger of exceeding the flow capacity of this pump at the fuel pressures it operates at.

Supercharged and turbocharged engines consume more fuel per HP they produce compared to naturally aspirated engines. The accepted "industry standard" for fuel consumption of these types of engines is 0.65 lbs of fuel per HP produced (BSFC=0.65). This data is represented in the red (bottom) line in the above chart. As you can clearly see, the EP376 fuel pump cannot support nearly as much horsepower on a super/turbocharged engine as it could on a naturally aspirated engine because of the increased fuel demands of the boosted engine per HP made. To further complicate matters, super/turbocharged engines typically run higher fuel pressures in order to overcome manifold boost pressure to maintain a consistent flow rate of the injectors (the 3800 Series II SC engine's fuel pressure is 60psi at 10psi of manifold boost pressure). As demonstrated in the above chart, the EP376 fuel pump cannot even support 300 crank HP when fuel pressures rise to 60psi or beyond.

Furthermore, stock OE-replacement pumps meant for naturally aspirated duty are usually not designed to operate at the higher pressures found in SC/turbo applications. Asking a pump like the EP376 to work in an environment with consistently higher pressures than what it was designed for is asking it to work harder than it was ever meant to. So the question is how long will it last? Well that depends on the quality of it's construction and the quality of the components used in it.

So what pump should you use? Well, you should use a fuel pump that is capable of supplying enough fuel volume at the pressure your application demands. If you are looking for an OE-replacement type fuel pump and your boosted engine only puts out up to about 300 crank HP, then you would probably be ok using something like a USA-made AC Delco EP-381 / Delphi FE0114 pump. However, GM, Delco, and Delphi have recently started outsourcing a lot of their manufacturing to China; and the Chinese-made parts are not of as good of a quality (or as capable) as the older, USA-made parts. For this reason, you may want to consider going with an aftermarket performance pump that has good reviews.

The aftermarket offers several different models of pumps, some manufacturers make pumps for many different vendors which are sold under other brand names such as Holley or even some OE-replacement units. For example, Walbro offers several high performance models: 190 lph (liters per hour), 190 lph-high pressure, 255lph, and 255lph-high pressure. Typically, the high pressure pumps are designed for use in forced induction applications where higher pressures are required of the fuel system. (The 255lpr walbro pumps will support over 550 crank HP on a turbo/supercharged engine @ 60psi of pressure.) Walbro offers several different designs of these pumps made for various vehicle applications. Below is a list of vendors who sell the Walbro line:

www.autoperformanceengineering.com

www.fullthrottlespeed.com

www.precisionturbo.net

Make sure you are buying a Genuine Walbro (or other brand name of your choice) fuel pump and not a Chinese-made counterfeit! For example, counterfeit Walbro pumps started flooding the market a few years ago and these have a very high failure rate. As always, read customer reviews and make sure the vendor offers a good warranty!

If you are going to install one of these high-performance fuel pumps into your car, and your car still has the factory fuel pump wiring, then I also recommend either upgrading your vehicle's fuel pump wiring circuit or installing a "hot-wire" kit. (see below)

Hot Wire Fuel Pump Kits

What are "hot wire" fuel pump kits? A hot-wire kit is a wiring kit that routes power to the fuel pump from the highest voltage/amperage power source on the vehicle -- the alternator B+ terminal. When is a hot-wire kit required? Hot wire kits are required primarily in applications where high fuel pressures or stronger fuel pumps are required or installed. Higher fuel pressures than stock put a higher electrical load on the vehicle's fuel pump electrical circuit. Higher performance aftermarket fuel pumps typically require more current (amperage) to operate at peak performance. Most OEM vehicle fuel pump wiring circuits are insufficient for the task. The hot wire method of getting higher current and voltage to the fuel pump usually involves running a larger than OEM gauge fuel pump power wire directly from the alternator's B+ terminal, thru a properly rated fuse, back to the fuel tank where an additional relay is attached to the chassis and is activated by the vehicle's OEM fuel pump wiring circuit. When installing a hot wire kit, special care must be taken to protect the wiring from moving and hot parts, as well as road debris and pinching from vehicle frame movement. www.casperselectronics.com sells a hot-wire fuel pump kit for most popular vehicles or you can build one yourself from parts that can be purchased from any automotive parts store. If you have higher than stock fuel pressure or have installed a high-performance aftermarket fuel pump but have not upgraded the vehicle's fuel pump wiring circuit; chances are your modifications are putting great strain on the vehicle's fuel pump wiring circuit and starving your fuel pump of much needed current and voltage which can result in insufficient volume of flow and pressure output. Instructions on how to perform the "Hot Wire" upgrade on Fieros can be found here.