2005 Pontiac Grand Prix GXP LS4 DoD 4T65E TAPShift powertrain swap into a Pontiac Fiero

PAGE 2

A couple of things I

have noticed about this engine is it shares a lot of the standard architecture

with the LS1 series of engines, except for the bellhousing bolt pattern, starter

mounting location, shorter crank, and more compact assy/belt drive setup. The

transmission is actually going to create some issues because GM didn't cast in

extra support in the area of the left rear mount -- probably because it wasn't

used in the Grand Prix. I already have an idea of how to work around this issue

so I can use my 4-corner mount system that doesn't require a dog-bone. Stock

this powertrain only used 3 lower mounts (two on the pass side and one on the

driver's side), which would require the use of a dog bone on the driver's side

-- where no such provisions exist on the Fiero chassis. One of the goals I have

for this swap is to modify the Fiero chassis as little as possible (if at all).

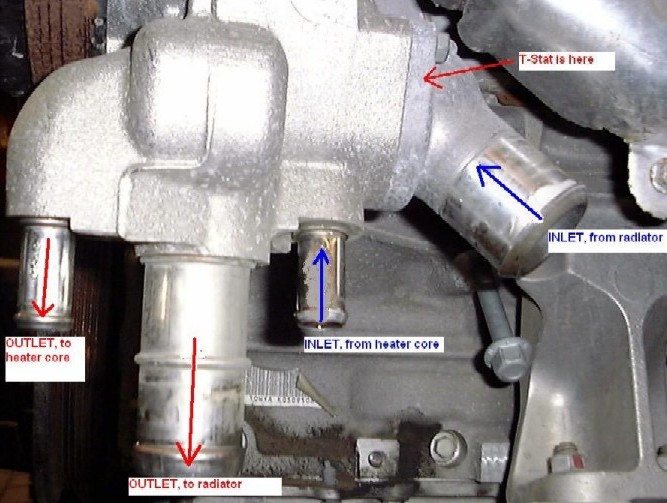

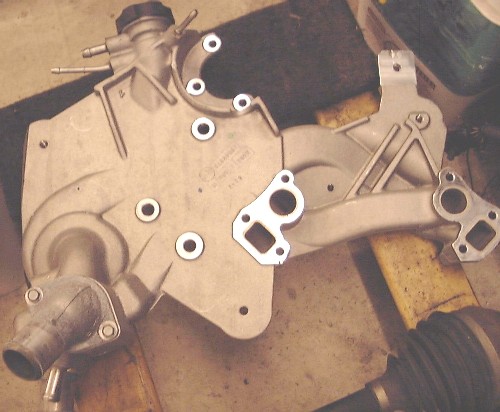

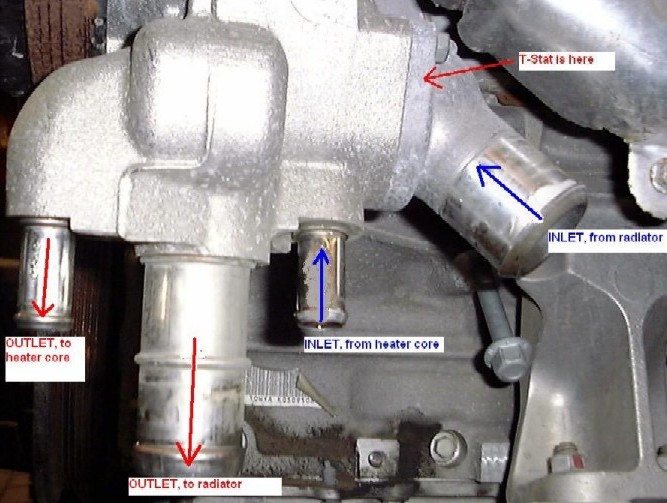

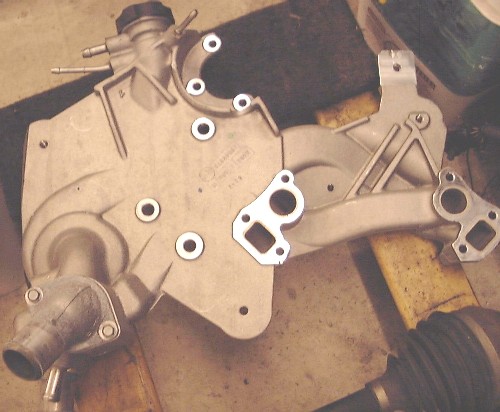

The front cover / water pump housing used on this engine is quite ingenious. All

coolant connections are located in this cover as well as the fill point for the

entire cooling system (the grand prix's radiator did not have a fill point on

it). Below is a picture of the T-stat housing and all heater hose and radiator

hose connections, which are located just behind and below the water pump.

On this engine the

starter is mounted to the transmission which is unique. The transmission case

has a special casting to accomodate this.

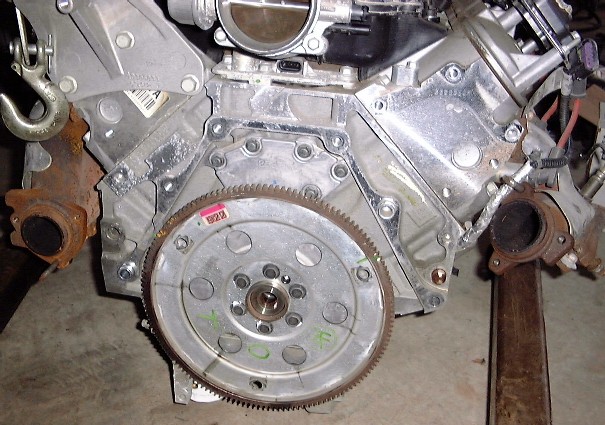

Below are some pictures of the auto trans flexplate (flywheel) and back of the block...

This flexplate does

NOT have a counterbalance weight; but it does have the FWD torque converter bolt

pattern (for the larger, 258mm converter like the 3800 SC engines use).

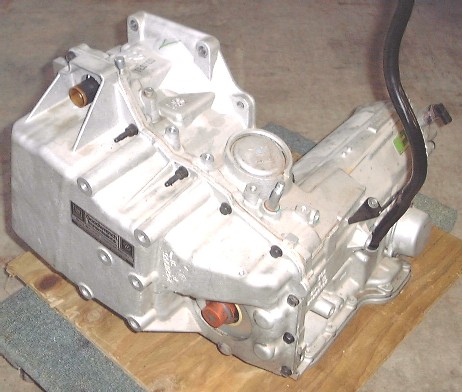

Here are some pics of the transmission, off the engine...

Below is a picture

of the area of the left rear mount area of this trans where GM didn't cast in

extra beef because no mounts were used in this location on this case, in the

cars it was put into... A few of the holes are not even tapped or drilled all

the way either.

I used a lathe to make some metal bushing sleeves I will later use for motor/trans mounts and some aluminum inserts for mock-up when I weld everything together. I plan to use rubber engine cradle bushings from an 84-87 Fiero for the mount bushings; they have an interference fit to these sleeves so they have to be pressed in.

Swap Page

1

2

3

4

5

6

7

8

9

10

11

12

13