2005 Pontiac Grand Prix GXP LS4 DoD 4T65E TAPShift powertrain swap into a Pontiac Fiero

PAGE 8

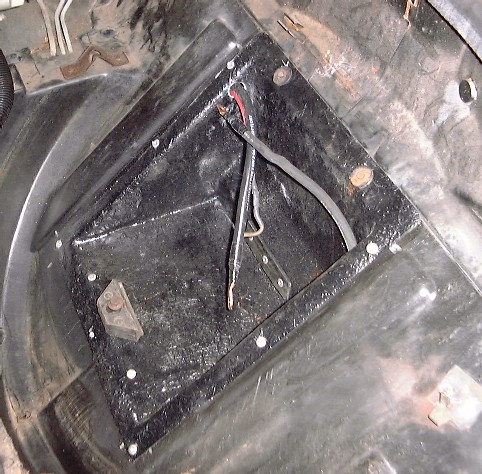

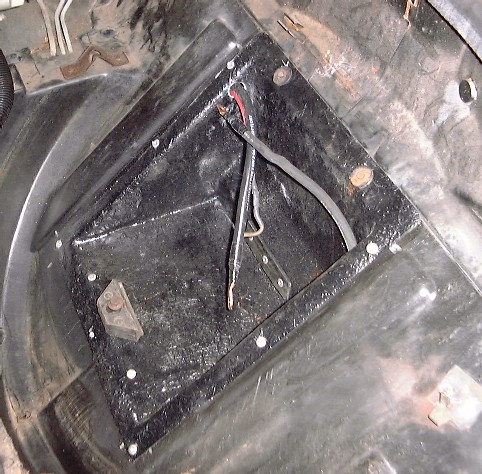

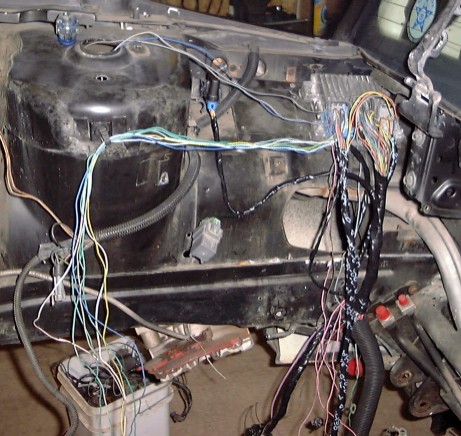

Battery is getting

relocated to the front using a kit from norm's fiberglass. I modified the tray

by adding provisions for "tying down" the battery in case no spare tire is going

to be present (stock spare won't work with the 12" brake upgrade that is going

on this car).

Got started on the exhaust system and built it as far as to the cats. Will finish it up once the engine goes back in for the last time.

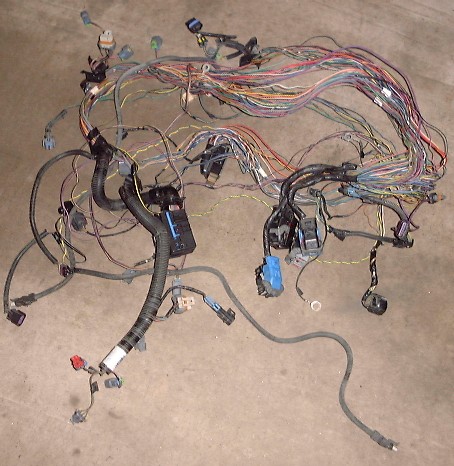

Below is a picture

of the LS4 engine and transmission wiring harness with most of the loom removed.

I took a few measurements before I removed the engine/trans from the car this

last time so I can get as much rewiring done as possible with the engine out.

Saves me from having to lean over into the engine compartment as much.

For ECM and TCM

mounting I recycled some of the fiberglass front spare tire well I had to cut

out for the battery box. The cases of the ECM and TCM should never be mounted to

a metal surface that is grounded to the chassis. The reason why is because if

the ground strap ever became severed from the engine to the chassis, or from the

engine to the battery (but still connected from battery to chassis); high

current could go thru the computers and damage them. GM keeps the cases to their

computers isolated from chassis ground for this reason.

Not pictured is the

wiring I have already completed for positive and ground supply from the battery

to chassis, engine, and alternator. The battery relocation kit comes with 4ga

cable to run from the pos battery term to the starter; but for this swap I

elected to upgrade this to 2ga because of the V8. I did use the 4ga cable to

connect the starter to the Fiero's original power distribution block. I also

pulled the clutch line, shifter, and shift/throttle cables from the car (since

it is getting changed over from a manual to auto trans). Installed the auto

trans cooler lines and I am working on mounting the fly-by-wire gas pedal

assembly.

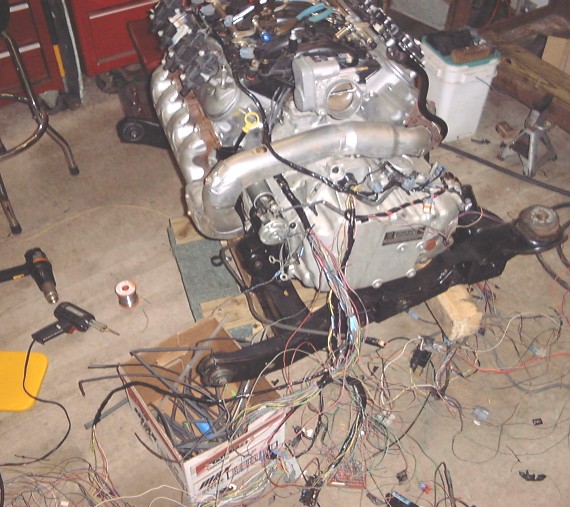

Probably the most time consuming single job of any swap involving an EFI engine

and electronic auto transmission is the wiring. Sure I could have taken a short

cut here and not modified the original LS4 wiring much but that's not how I do

things. Pretty much every wire in the harness had to have its length changed so

it could be routed the way I wanted. OEM had the wires going over the top of the

intake for almost every device/sensor and I just don't like it done that way. I

like to keep as much off the intake as possible and you can see the difference

in the pictures below...

In progress...

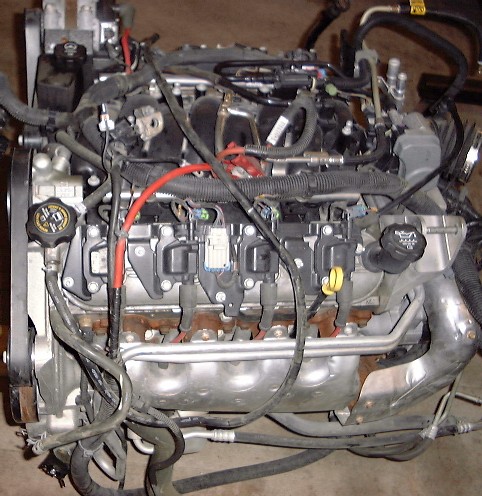

Here's what it

looked like stock...

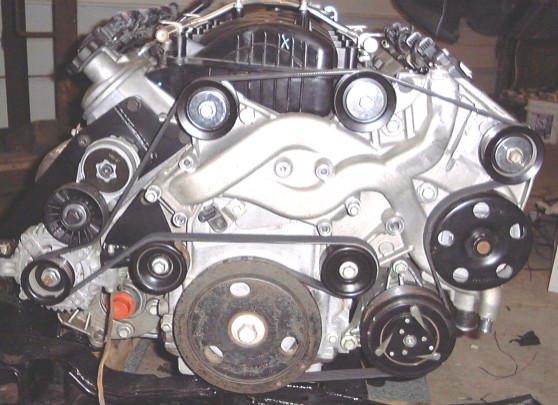

Here's what it looks

like now...

Still have quite a bit to do including integrate the engine harness into the vehicle but it's getting there.

NEW ASSY BELT ROUTING: (uses a 102.0" 6-rib serpentine belt)

Swap Page 1 2 3 4 5 6 7 8 9 10 11 12 13